information to be updated

Natural Gas High-Pressure Ball Valve is a control device specifically designed for natural gas transmission systems, suitable for high-pressure applications such as city gate stations, long-distance pipelines, and industrial gas supply. This type of valve features high-pressure sealing characteristics, operating pressure ranges from PN16 to PN100, and can reliably cut off or connect natural gas media. Its core performance includes fire-resistant safety structure, anti-static design, and low-temperature sealing capability, meeting international standards such as API 6D. The product highlights of the natural gas high-pressure ball valve are mainly reflected in its full-bore flow channel design, explosion-proof operating mechanism, and special anti-corrosion treatment process, ensuring long-term stable operation in harsh natural gas environments containing hydrogen sulfide and other pollutants. This specially designed natural gas high-pressure ball valve provides a safe and reliable control solution for gas transmission and distribution systems.

Although they are both called valves, ball valves are quite different from the "ordinary valves" we usually see, which require several turns to operate, like a faucet (such as globe valves or gate val...

View MoreThe purpose of a ball valve is to provide a reliable control point for the flow of substances in a pipeline. Its objective is very clear: to allow flow when desired and to stop it immediately when nee...

View MoreA ball valve is like a "rotating switch" in a water pipe. Its core component is a sphere with a hole in the middle, and the flow of water is controlled by rotating this sphere. ● Core Structure and ...

View More1. What is a Hydraulic Ball Valve? A hydraulic ball valve is a type of quarter-turn valve that uses hydraulic pressure to actuate the ball, rather than electric or pneumatic power. Core Function: It u...

View MoreIn the field of energy transmission and industrial fluid control, natural gas high-pressure ball valves play a crucial role. As the "throat" of the pipeline system, their performance directly impacts the safety and operational efficiency of the entire transmission and distribution network.

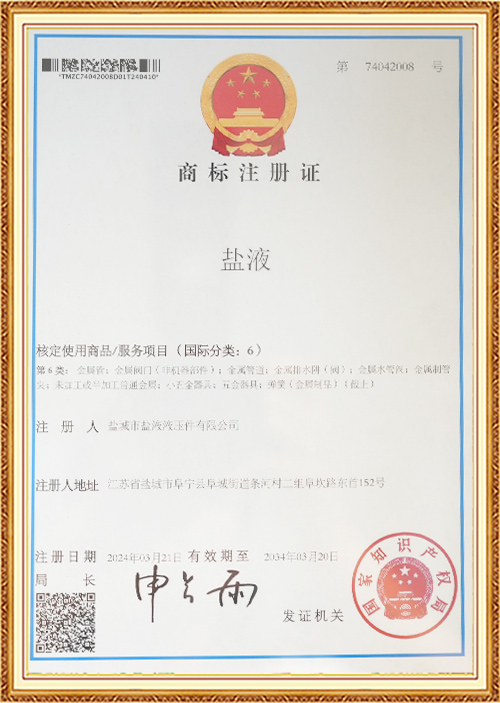

Yancheng Yanye Hydraulic Parts Co., Ltd., leveraging its profound industry experience, deeply integrates precision hydraulic technology with high-end valve manufacturing processes, and is committed to providing global customers with fluid control solutions for extreme operating conditions.

Technical Content and Industry Applications of Natural Gas High-Pressure Ball Valves

I. Structural Design and Sealing Logic

The core of a natural gas high-pressure ball valve lies in the cooperation between its ball and seat. When handling natural gas, a flammable, explosive, and permeable medium, the reliability of the seal is the primary consideration.

Fixed Ball Design: In high-pressure environments, the ball is fixed by upper and lower bearings, preventing displacement due to media pressure. This effectively avoids excessive wear of the sealing pair and ensures stable switching torque under high-pressure differences.

Bidirectional Sealing Mechanism: A dual sealing structure is adopted on both the upstream and downstream sides. Even if the pressure fails on one side, the other side can still maintain blockage, greatly improving pipeline safety.

Fireproof and Anti-static Construction: Considering the physical characteristics of natural gas, electrostatic discharge devices are installed between the valve stem and the ball and valve body, and fireproof sealing rings are included to ensure that basic shut-off functions can still be maintained in extreme situations such as fires.

II. Material Selection and Process Control

Yancheng Yanye Hydraulic Parts Co., Ltd. adheres to stringent fluid dynamics standards in material selection to cope with potential corrosion and erosion in natural gas transportation.

Corrosion-Resistant Substrate: For acidic natural gas containing hydrogen sulfide or carbon dioxide, specially heat-treated alloy steel or stainless steel is selected to enhance the material's resistance to stress corrosion cracking at the microstructural level.

Surface Hardening Treatment: The ball surface usually adopts supersonic spraying or chemical plating technology to significantly improve surface hardness and smoothness, reduce the friction coefficient, and extend the service life of the equipment under frequent opening and closing.

III. Integration of Drive and Control Systems

Modern natural gas transportation demands a high degree of automation. Hydraulic Linkage Advantages: Combining our expertise in saline hydraulic systems, high-pressure ball valves are often equipped with precision hydraulic actuators. Compared to electric or pneumatic solutions, hydraulic drives provide greater output torque and more precise proportional control, making them suitable for emergency shut-off tasks in large-diameter, long-distance pipelines.

Intelligent Monitoring: The integration of valve position sensing and pressure feedback systems allows for real-time transmission of fluid control status to the central control system, enabling predictive maintenance.

Core Parameters and Function Comparison Table

| Functional Module | Key Technical Characteristics | Industrial Value & Application |

| Seating Configuration | Metal-to-Metal Seat / Soft Seating (PTFE/Devlon) | Provides robust resistance against particulate abrasion or achieves zero-leakage (Bubble Tight) standards for clean gas. |

| Stem Design | Anti-Blowout Stem Structure | Prevents the stem from being ejected under extreme pressure surges, ensuring operator safety and system integrity. |

| Pressure Relief | Automatic Cavity Pressure Relief (Self-Relieving) | Automatically discharges abnormal pressure buildup within the valve cavity to the pipeline, protecting the seats and body. |

| Lubrication System | Emergency Sealant Injection Fitting | Allows for the injection of emergency synthetic grease to create a temporary seal if the primary sealing surface is damaged. |

| Fire-Safe Design | API 607 / API 6FA Compliance | Ensures the valve maintains a secondary metal seal to prevent catastrophic leakage during and after external fire exposure. |

| Anti-Static Device | Spring-loaded Plunger/Grounding | Eliminates static electricity buildup between the ball, stem, and body, preventing sparks in volatile gas environments. |

FAQ: Frequently Asked Questions about High-Pressure Natural Gas Ball Valves

Q1: Why are fixed ball valves preferred over floating ball valves in high-pressure natural gas pipelines?

In high-pressure environments, the ball of a floating ball valve transmits all the pressure to the downstream valve seat, leading to excessive pressure on the sealing surface. This not only makes opening and closing difficult but also easily causes valve seat deformation. Fixed ball valves support the ball with bearings, transferring the pressure load to the valve body structure, ensuring operational flexibility and long-lasting sealing under high pressure.

Q2: How to address "cavitation" and "erosion" phenomena during natural gas transportation?

This is mainly solved by optimizing the flow channel design and improving material hardness. Yancheng Yanye Hydraulic Parts Co., Ltd. uses precise flow field simulation analysis to reduce turbulence when the fluid passes through the valve. Combined with high-hardness surface treatment technology, this effectively resists long-term erosion from small solid particles in the medium.

Q3: What should be paid attention to in the maintenance of hydraulic drive mechanisms in ball valves?

The cleanliness of the hydraulic system's fluid is crucial. The quality of the hydraulic oil should be checked regularly to ensure that the actuator's seals are not aging. The integrated solutions provided by Yanye Hydraulic usually have a very high degree of system integration, simplifying on-site maintenance procedures and improving system response speed.

Q4: What is the practical significance of the "Double Block and Bleed (DBB)" function in high-pressure ball valves?

The DBB function allows the pressure in the valve cavity to be released through a drain valve when the valve is closed. This not only verifies whether the valve's sealing performance is intact but also facilitates online maintenance or packing replacement without shutting down the entire pipeline.