Although they are both called valves, ball valves are quite different from the "ordinary valves" we usually see, which require several turns to operate, like a faucet (such as globe valves or gate val...

View MoreThe purpose of a ball valve is to provide a reliable control point for the flow of substances in a pipeline. Its objective is very clear: to allow flow when desired and to stop it immediately when nee...

View MoreA ball valve is like a "rotating switch" in a water pipe. Its core component is a sphere with a hole in the middle, and the flow of water is controlled by rotating this sphere. ● Core Structure and ...

View More1. What is a Hydraulic Ball Valve? A hydraulic ball valve is a type of quarter-turn valve that uses hydraulic pressure to actuate the ball, rather than electric or pneumatic power. Core Function: It u...

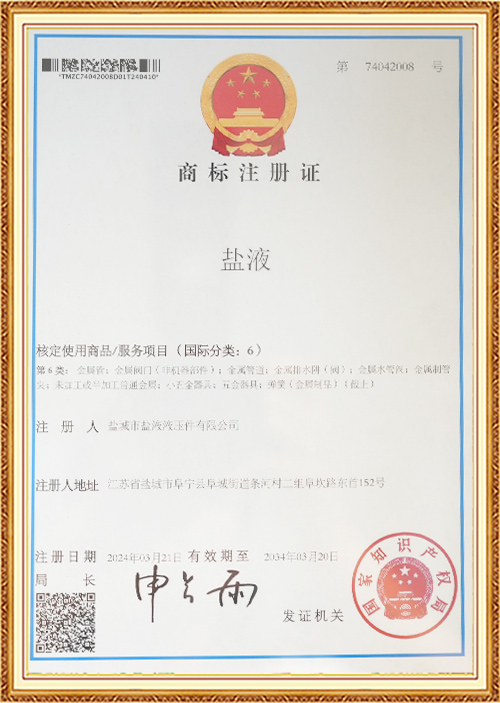

View MoreIn modern industrial fluid control systems, hydraulic ball valves, as key actuators for media cutoff and flow distribution, have performance stability that directly impacts the safety of the entire hydraulic circuit. Yancheng Yanye Hydraulic Parts Co., Ltd., a high-tech private enterprise specializing in hydraulic systems and integrating R&D and manufacturing, has accumulated profound industry insights into the design logic and application characteristics of hydraulic ball valves through its long-term production and processing practices.

I. Core Design Logic of Hydraulic Ball Valves

The design of hydraulic ball valves essentially revolves around "zero leakage" and "low flow resistance." Its core component is a sphere with a through-hole, which opens and closes the channel by rotating 90 degrees.

Full Bore and Flow Resistance Control: In hydraulic systems, energy loss is usually manifested as pressure drop. Hydraulic ball valves typically adopt a full-bore design, meaning that when the valve is fully open, the internal channel diameter is consistent with the pipe's inner diameter, allowing fluid to pass through with almost no obstruction. This design greatly reduces turbulence and pressure loss as the fluid passes through the valve, ensuring the efficiency of the system's actuators.

Mutual Compensation of Sealing Pairs: The sealing of the ball valve mainly relies on the tight fit between the ball and the valve seat. Yancheng Yanye Hydraulic Parts Co., Ltd. pays special attention to the grinding precision of the sealing pairs during the manufacturing process. Under high pressure, the media pressure will push the ball to move slightly, pressing it more tightly against the downstream valve seat, forming a "pressure-assisted sealing" effect, thus ensuring excellent cutoff performance even under high pressure.

II. Structural Characteristics and Functional Evolution

According to different working conditions, hydraulic ball valves have distinct structural differences, and these design details determine their performance in complex hydraulic circuits.

1. Fixed and Floating Designs

Floating Ball Valve: The ball is floating, and under the action of media pressure, the ball can produce a certain displacement and press tightly against the sealing ring at the outlet end. This structure is simple, but under extremely high pressure or large diameters, it requires extremely high pressure resistance from the sealing ring.

Fixed Ball Valve: The ball has upper and lower rotating shafts, and its position is fixed. Under pressure, the ball does not move; instead, the valve seat is pushed towards the ball by a spring or media pressure. This design is more suitable for ultra-high-pressure systems and requires relatively low operating torque.

2. Expansion of Multi-way Functionality

In addition to the basic two-way shut-off function, hydraulic ball valves are often designed with three-way or four-way structures (such as L-type or T-type) to achieve switching, merging, or splitting of hydraulic oil flow. This integrated design reduces the number of connectors in the pipeline, lowering potential leakage points in the system.

III. Materials Science and Surface Treatment

In the hydraulic field, the medium often has a certain corrosiveness, and the system pressure fluctuates drastically. Yancheng Yanye Hydraulic Parts Co., Ltd. emphasizes the balance between fatigue resistance and wear resistance in material selection and processing technology.

Application of forged valve bodies: Compared with castings, forged valve bodies have a denser metal structure and can withstand higher pulse pressures without generating microcracks. This is crucial for heavy-duty construction machinery or high-pressure power stations.

Ball hardening treatment: To improve the service life of the switch, the ball surface is usually treated with high-frequency quenching, chrome plating, or electroless nickel plating. The extremely high surface finish not only reduces the opening and closing torque but also effectively prevents small particles in the medium from scratching the sealing surface.

IV. Professional Evaluation of Selection Dimensions

In practical engineering applications, selecting a suitable ball valve requires comprehensive consideration of multiple variables in fluid dynamics.

Medium compatibility: The swelling effect of hydraulic oil (mineral oil, water-glycol, or phosphate ester high-flammability fluid) on sealing materials (such as nitrile rubber, fluororubber, or polytetrafluoroethylene) must be considered.

Environmental adaptability: In environments with salt spray, extreme high and low temperatures, or severe vibration, the external coating of the valve and the design of the handle locking device are equally important.

Opening and closing frequency: For working conditions requiring frequent switching, the wear resistance cycle of the valve seat material must be evaluated.

V. Hydraulic Ball Valve Technology Comparison Table

To provide a clear understanding of different application scenarios, the following table summarizes the key characteristics of hydraulic ball valves:

| Characteristic | Soft-Seated Hydraulic Ball Valve | Hard-Seated (Metal) Ball Valve | High-Pressure Manifold Ball Valve |

| Sealing Material | PTFE / POM (Polyoxymethylene) | Special Alloy / Tungsten Carbide | Advanced Composite Materials |

| Key Advantages | Zero leakage, low operating torque | High-temp & erosion resistance | Compact design, high integration |

| Applicable Media | Clean mineral hydraulic oils | Contaminated media or high-temp fluids | Multi-port hydraulic control circuits |

| Connection Types | NPT / BSPP Threaded | Socket Weld / Flanged | Subplate / Manifold Mounting |

VI. Frequently Asked Questions (FAQ)

Q1: Why do hydraulic ball valves become difficult to operate under high pressure?

A: This is mainly due to the increased friction caused by the medium pressure acting on the ball. Yancheng Yanye Hydraulic Parts Co., Ltd. usually improves this phenomenon in its designs by optimizing the force-bearing area of the valve seat or using gaskets with a low friction coefficient. If an old piece of equipment suddenly becomes difficult to operate, it is necessary to check for internal impurities or blockages.

Q2: How to determine if a ball valve has internal leakage?

A: The most direct method is to observe whether there is an abnormal pressure increase on the pressure gauge after the valve, or to disconnect the downstream pipeline in the closed state and observe whether any medium flows out. Internal leakage is usually caused by scratches on the sealing surface or aging of the sealing ring.

Q3: Can hydraulic ball valves be used as throttling valves?

A: It is not recommended. Ball valves are designed for full open or full closed operation. In a semi-open state, the high-speed fluid will cause serious erosion and damage to the edge of the ball and the valve seat (i.e., "cavitation"), shortening the service life and leading to seal failure.

Q4: How does Yancheng Yanye Hydraulic Parts Co., Ltd. balance cost and quality in ball valve development?

A: Relying on extensive production and processing experience, the company effectively controls production costs by optimizing manufacturing processes and implementing refined management, while ensuring material standards and processing accuracy. This allows them to provide users with more cost-effective professional fluid control solutions.

Q5: Are there any directional requirements when installing hydraulic ball valves?

A: Ordinary bidirectional ball valves usually do not have strict directional requirements, but some unidirectional sealing ball valves with pressure relief holes or specific compensation structures must be installed strictly according to the arrow direction marked on the valve body; otherwise, it may lead to seal failure.