information to be updated

SAE type High-pressure Ball Valves are industrial pipeline control devices conforming to SAE J518 standards, specifically designed for hydraulic systems and high-pressure conditions. These products utilize a standardized flange connection structure, ensuring quick docking and reliable sealing with compatible SAE interface devices. The core performance of SAE-type high-pressure ball valves lies in their high-pressure resistance and zero-leakage sealing capability, with operating pressures up to 6000 PSI. Structural highlights of this series include a low-torque operating design, bidirectional flow characteristics, and corrosion-resistant valve body materials, enabling stable operation in various harsh media environments. This standardized design of SAE-type high-pressure ball valves is widely used in engineering machinery, hydraulic systems, and industrial equipment, providing a reliable solution for high-pressure fluid control.

Although they are both called valves, ball valves are quite different from the "ordinary valves" we usually see, which require several turns to operate, like a faucet (such as globe valves or gate val...

View MoreThe purpose of a ball valve is to provide a reliable control point for the flow of substances in a pipeline. Its objective is very clear: to allow flow when desired and to stop it immediately when nee...

View MoreA ball valve is like a "rotating switch" in a water pipe. Its core component is a sphere with a hole in the middle, and the flow of water is controlled by rotating this sphere. ● Core Structure and ...

View More1. What is a Hydraulic Ball Valve? A hydraulic ball valve is a type of quarter-turn valve that uses hydraulic pressure to actuate the ball, rather than electric or pneumatic power. Core Function: It u...

View MoreIn the field of modern hydraulic transmission and fluid control, the stability and safety of a system often depend on small but critical components. SAE type high-pressure ball valves, as core components for rapid opening, closing, and flow control in high-pressure pipelines, have a design and manufacturing precision that directly impacts the operating efficiency of the entire industrial system.

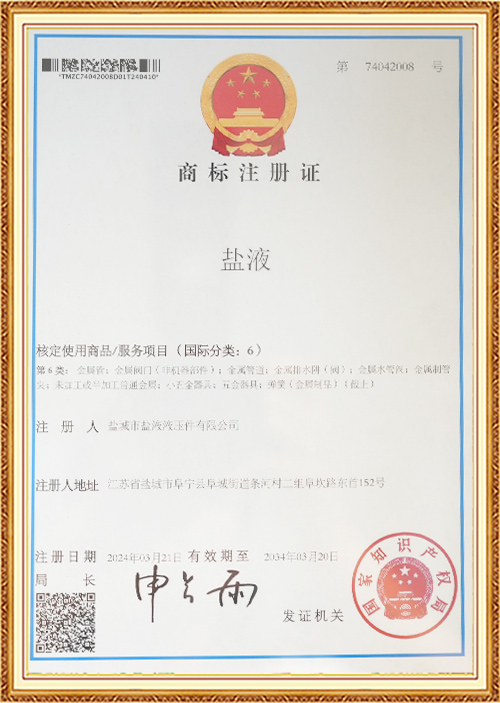

Yancheng Yanye Hydraulic Parts Co., Ltd. has been deeply involved in the manufacturing of hydraulic accessories for many years. With a profound understanding of high-pressure fluid characteristics and exquisite processing technology, they have perfectly integrated the high compatibility of the SAE standard with the high reliability of ball valves. Their SAE type high-pressure ball valves have become a trusted choice in many heavy industrial fields.

Core Design Philosophy of SAE Type High-Pressure Ball Valves

The reason why SAE type high-pressure ball valves perform exceptionally well under harsh working conditions in industries such as petroleum, chemical, and metallurgy stems from their unique design logic:

Optimized Flow Path and Low Pressure Drop: The ball valve adopts a full-bore design, where the diameter of the ball core channel is consistent with the inner diameter of the pipe. This structure minimizes turbulence during fluid flow, reduces pressure loss, and ensures stable operation of the system under high flow conditions.

High-Pressure Sealing Technology: Unlike ordinary valves, high-pressure environments demand almost perfect sealing. SAE type ball valves typically employ a self-compensating sealing structure, utilizing the fluid's own pressure to push the sealing seat towards the ball core, achieving a "tighter with increasing pressure" effect, effectively eliminating the risk of internal leakage.

Advantages of SAE Flange Connection: The use of SAE (Society of Automotive Engineers) standard interfaces makes the connection between the valve and the system pipeline more secure and easier to maintain. This connection method can withstand significant radial and axial loads and simplifies the installation process in confined spaces.

Yancheng Yanye Hydraulic Parts Co., Ltd.'s Technological Expertise

In the production of SAE type high-pressure ball valves, Yancheng Yanye Hydraulic Parts Co., Ltd. consistently prioritizes "excellent quality" in every aspect:

Material Selection and Performance Matching: For different industries and their specific media, such as corrosive fluids in the petroleum industry or ultra-high temperature media in the metallurgical industry, the company ensures that the valve body does not deform or fracture under extreme conditions through rigorous material selection. Precision Machining Process: The roundness and surface finish of the ball core are critical factors determining the valve's operating torque and sealing life. The company utilizes high-precision CNC machine tools and grinding technology to ensure that every ball core achieves a perfect, leak-free seal.

Multi-Industry Adaptability: From auxiliary systems in the power industry to pulp transportation in the paper industry, our hydraulic products demonstrate strong versatility and customization potential, providing reliable hydraulic control solutions for diverse industries such as energy and food processing.

Functional Characteristics Comparison of SAE Type High-Pressure Ball Valves

| Evaluation Dimension | Technical Performance Features | Industrial Value & Application |

| Sealing Reliability | Features a dynamic compensation sealing structure designed to withstand intense high-pressure surges. | Prevents media leakage, ensuring operational safety and environmental protection in sensitive sites. |

| Operational Efficiency | Precise |

Enables rapid emergency shut-off while significantly reducing manual labor intensity for operators. |

| Connection Stability | Adheres to standardized SAE flange and threaded interfaces for seamless system integration. | Minimizes the impact of mechanical vibrations and simplifies on-site assembly and maintenance. |

| Long-term Durability | Utilizes advanced surface strengthening treatments and high-hardness ball cores to resist wear. | Extends the equipment replacement cycle and effectively lowers costly system downtime. |

| Working Adaptability | Engineered to be compatible with water, hydraulic oil, and various chemical emulsions. | Meets the diverse requirements of the chemical, metallurgy, energy, and power generation industries. |

FAQ: Frequently Asked Questions about SAE Type High-Pressure Ball Valves

Q1: What is the biggest difference between SAE type ball valves and ordinary high-pressure ball valves?

A: The biggest difference lies in the interface standard and structural strength. SAE type ball valves strictly adhere to standards such as SAE J518, and their connection dimensions perfectly match the flange components of high-pressure systems. They place greater emphasis on fatigue resistance under pulsating pressure cycles, making them more suitable for industrial hydraulic systems sensitive to vibration and pressure transients.

Q2: Are there strict requirements regarding the flow direction when installing SAE type high-pressure ball valves?

A: Although most ball valves support bidirectional flow, it is generally recommended to install them according to the flow direction marked on the valve body to achieve optimal sealing performance and service life. In specific high-pressure conditions, the correct installation direction can effectively utilize fluid pressure to assist in sealing.

Q3: How to determine if this valve is suitable for corrosive media such as those found in the petroleum or chemical industries?

A: The key lies in the valve body material and the material of the internal sealing components. Yancheng Yanye Hydraulic Co., Ltd. will provide suitable recommendations based on the specific media composition. For example, for petroleum media containing hydrogen sulfide, it is necessary to select sulfur-resistant materials that have undergone special heat treatment and corrosion-resistant sealing components such as fluororubber.

Q4: Why are valves with SAE interfaces preferred in the power and metallurgical industries?

A: The large hydraulic power units involved in these industries require extremely high reliability in connections. SAE flange connections provide extremely strong torsional and vibration resistance, and during maintenance, the valve can be removed by simply unscrewing four bolts, without the need to cut the pipeline, greatly improving maintenance efficiency.