Product features and advantages

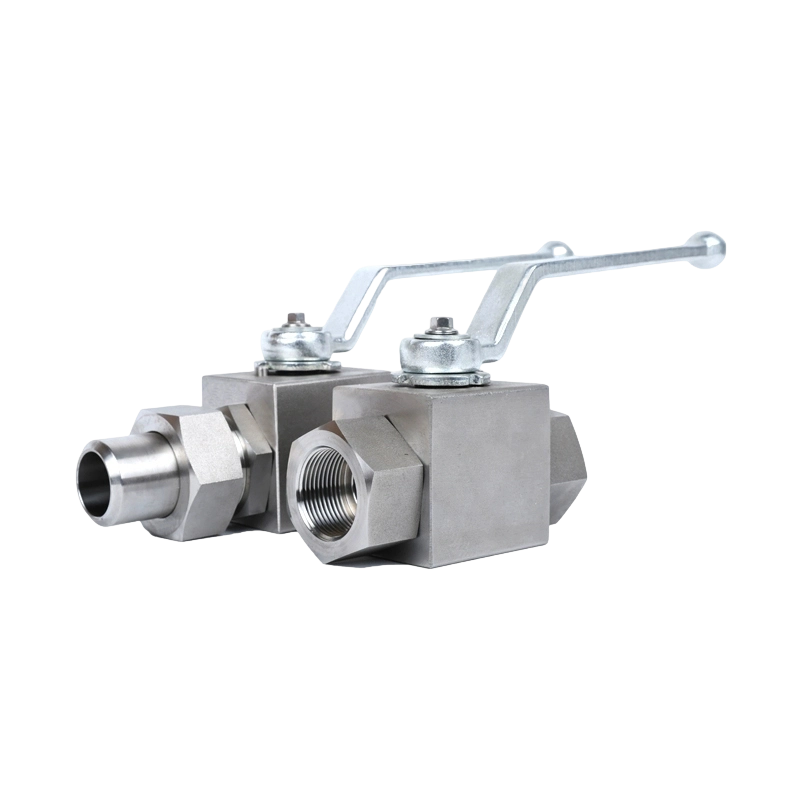

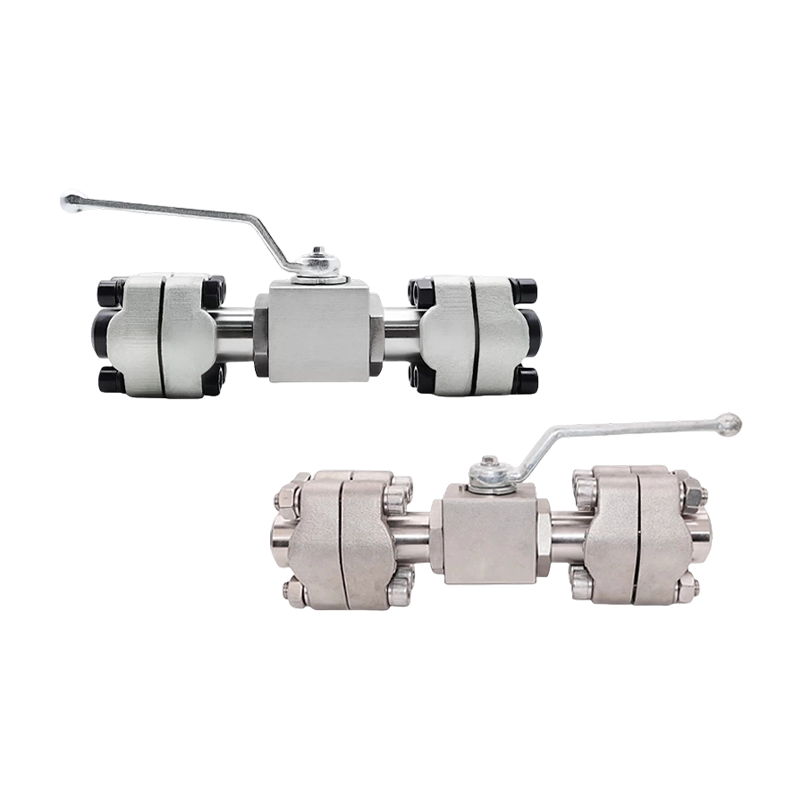

1. Butt weld connection: ultimate reliability

- Zero leakage is possible: the valve and the pipeline are welded together through the bevel to form a permanent connection, with no leakage point, the highest safety.

- Excellent anti-vibration: the welding connection strength is equivalent to the pipeline itself, can withstand extreme vibration and fatigue impact, life is far more than the threaded or clamp connection.

- Compact design: No extra flexible joints or connectors required, minimizing installation space.

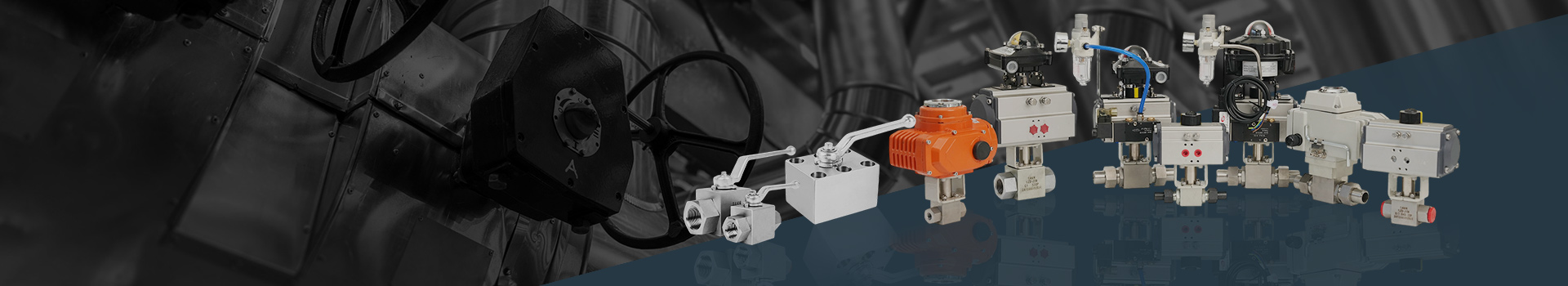

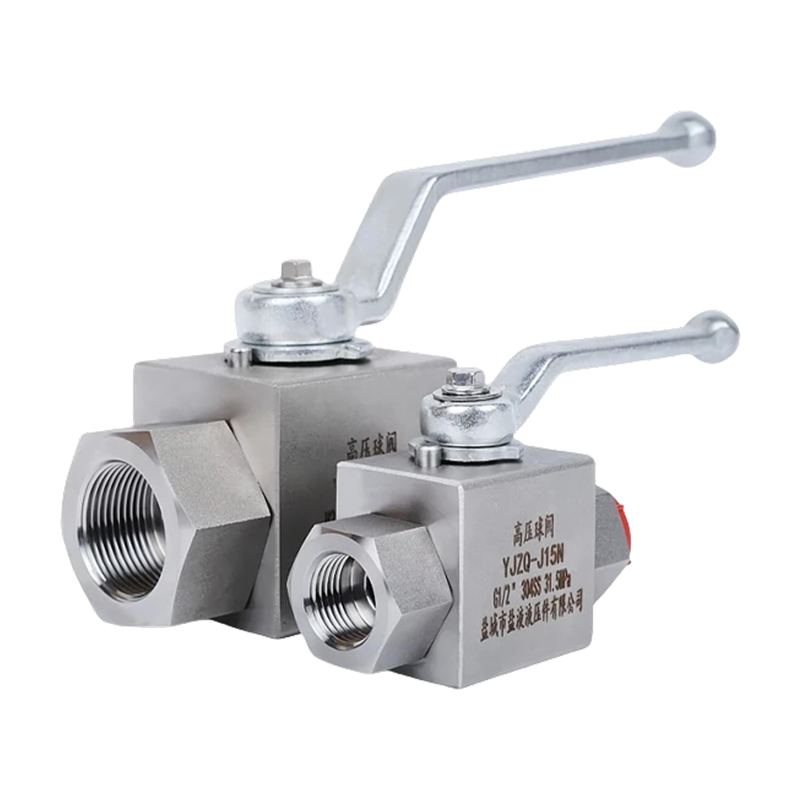

2. Method: Strong and durable

- High strength: The Square flange has better bending resistance and stronger connection rigidity than round flange.

- Easy installation: Connect to the device quickly with bolts, facilitating system integration and maintenance.

- High pressure: The flange connection can withstand high system pressure and uneven load.

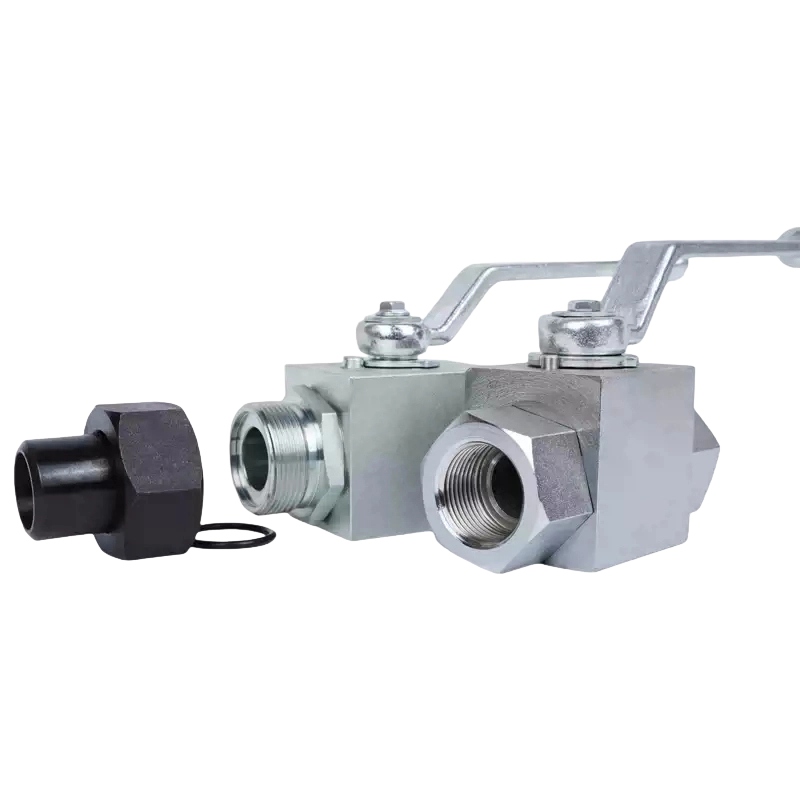

3. High voltage design and performance

- Thickened valve body: forged valve body is adopted, and the key parts are thickened to ensure safety under ultra-high pressure.

- Hard sealing technology: the surface of the ball core is hardened (such as hard chrome plating), forming metal to metal hard sealing with the valve seat, corrosion-resistant and long life.

4. Application scenarios are clear

- Pump outlet shut-off valve: directly welded to the outlet of the hydraulic pump as the main shut-off valve.

- Important operating mechanism inlet: Inlet installed in the cylinder or hydraulic motor to provide reliable isolation.

- High-pressure main pipeline node: used for critical pipeline nodes that require permanent and reliable connections.

English

English