Detailed Explanation of Product Features and Advantages

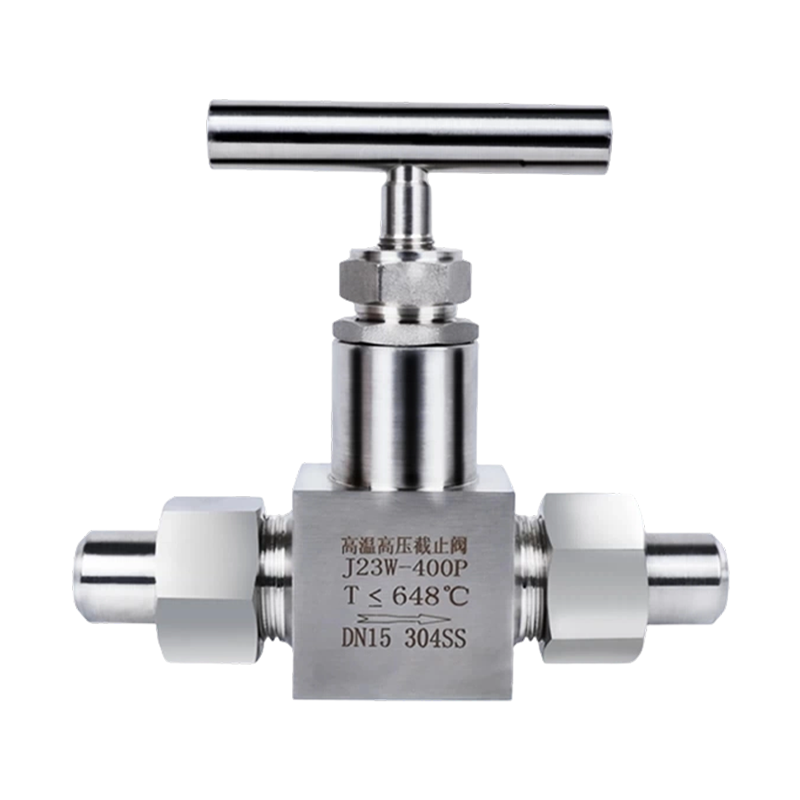

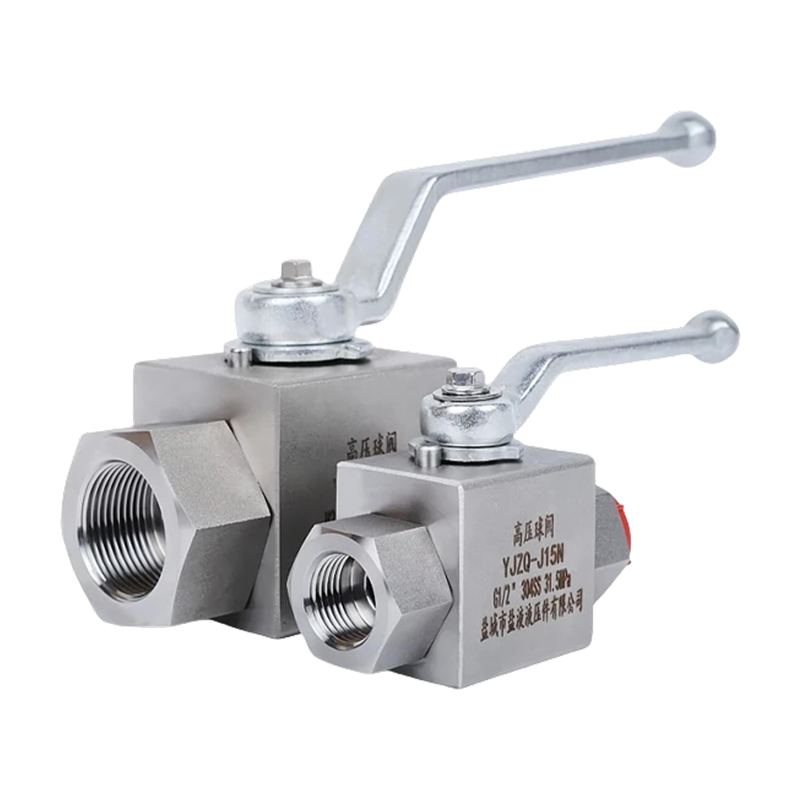

1. Stainless Steel Valve Body, Corrosion Resistant and Durable

- 304 Stainless Steel: A general-purpose chromium-nickel stainless steel with good corrosion resistance, suitable for most mildly corrosive media such as water, steam, and weak acid-alkali solutions.

- 316L Stainless Steel: Molybdenum-added, with stronger pitting corrosion and intergranular corrosion resistance, it is the first choice for chloride environments (such as seawater) and strong acid-alkali media.

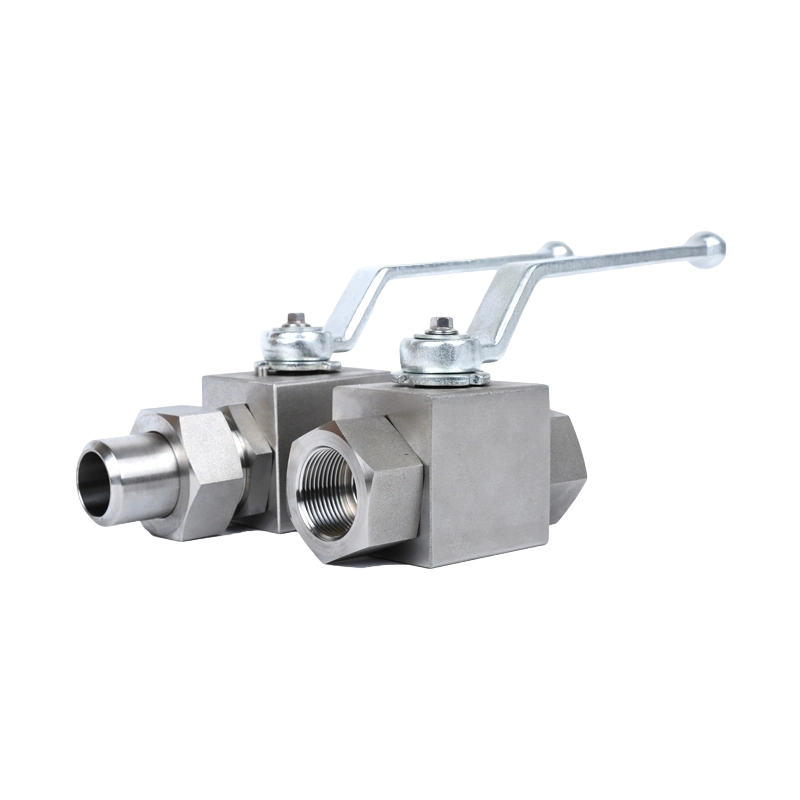

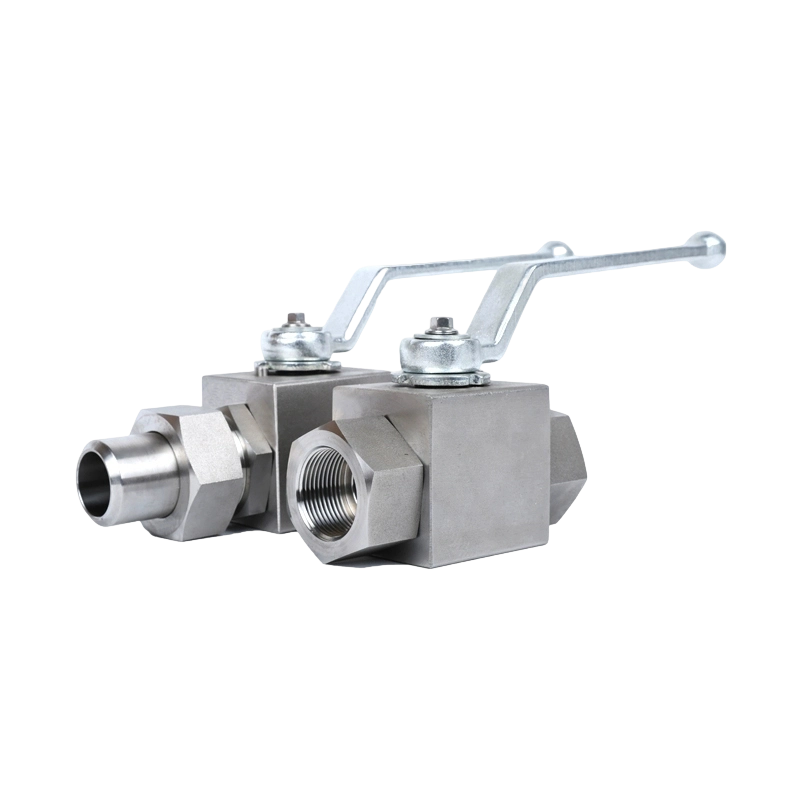

2. High-Pressure Design, Safety Foundation

- The valve body adopts a thickened wall design, and the structure is optimized through Finite Element Analysis (FEA) to ensure long-term stable operation under 31.5MPa and higher pressure.

- Strict factory testing: Each valve undergoes a strength test of 1.5 times the nominal pressure, with sufficient safety margin.

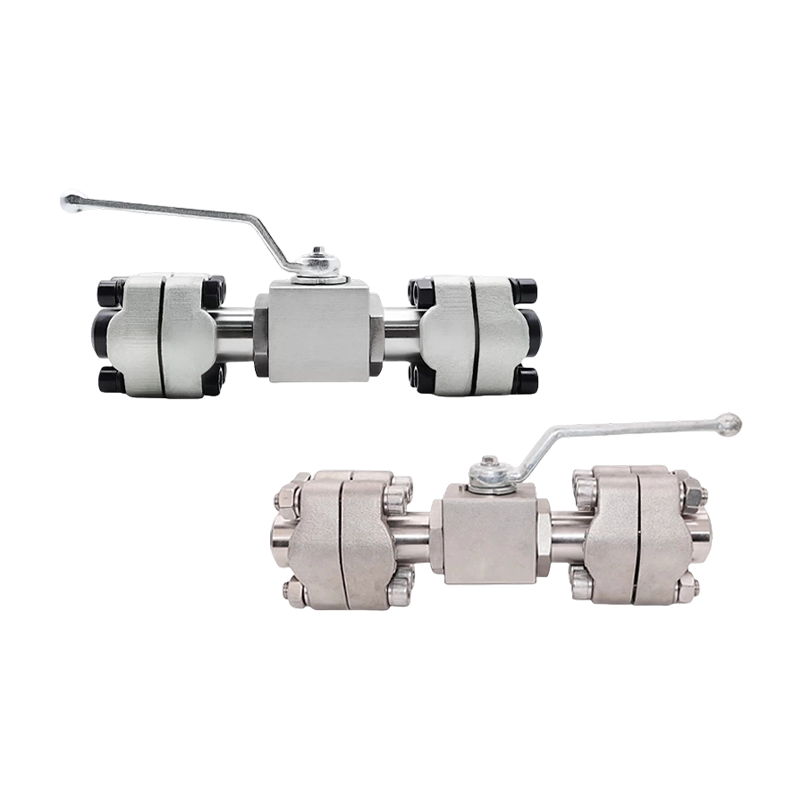

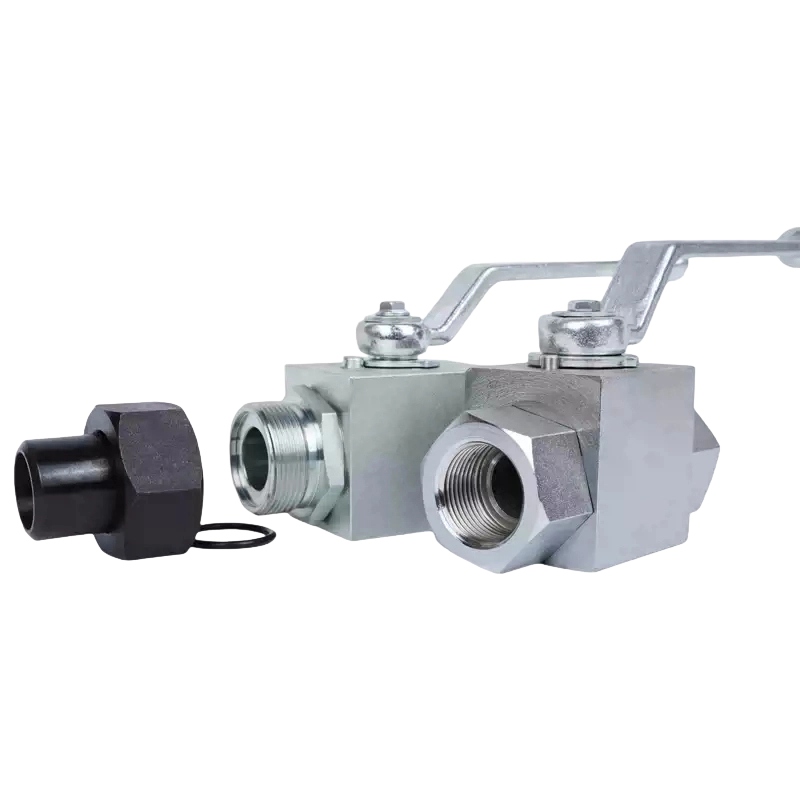

3. Thread Connection, Flexible and Convenient

- Internal Thread (Common in YJZQ): After installation, the outer wall of the pipeline is smooth, occupying small space, beautiful and anti-collision.

- External Thread: High connection strength, good anti-vibration performance, and easy installation.

- International Standards: Provides various thread standards such as BSP (British), G (Metric), NPT (American), meeting global procurement needs.

4. High-Temperature Sealing, Stable Performance

The valve seat sealing ring adopts reinforced PTFE (RPTFE), PPL (polyphenylene) or metal sealing, which can maintain elasticity and sealing performance at high temperatures, avoiding leakage caused by thermal deformation.

5. Precision Manufacturing, Smooth Control

- The ball surface is subjected to hard chrome plating or ultra-precision grinding, which is as smooth as a mirror, with low friction coefficient, small operating torque and light opening and closing.

- Quick Opening and Closing: A 90-degree right-angle rotation can realize full opening or full closing, facilitating quick cut-off or connection of fluid.

English

English